Low-carbon Hydrogen

A portfolio of technologies for low-carbon hydrogen production, purification and recovery

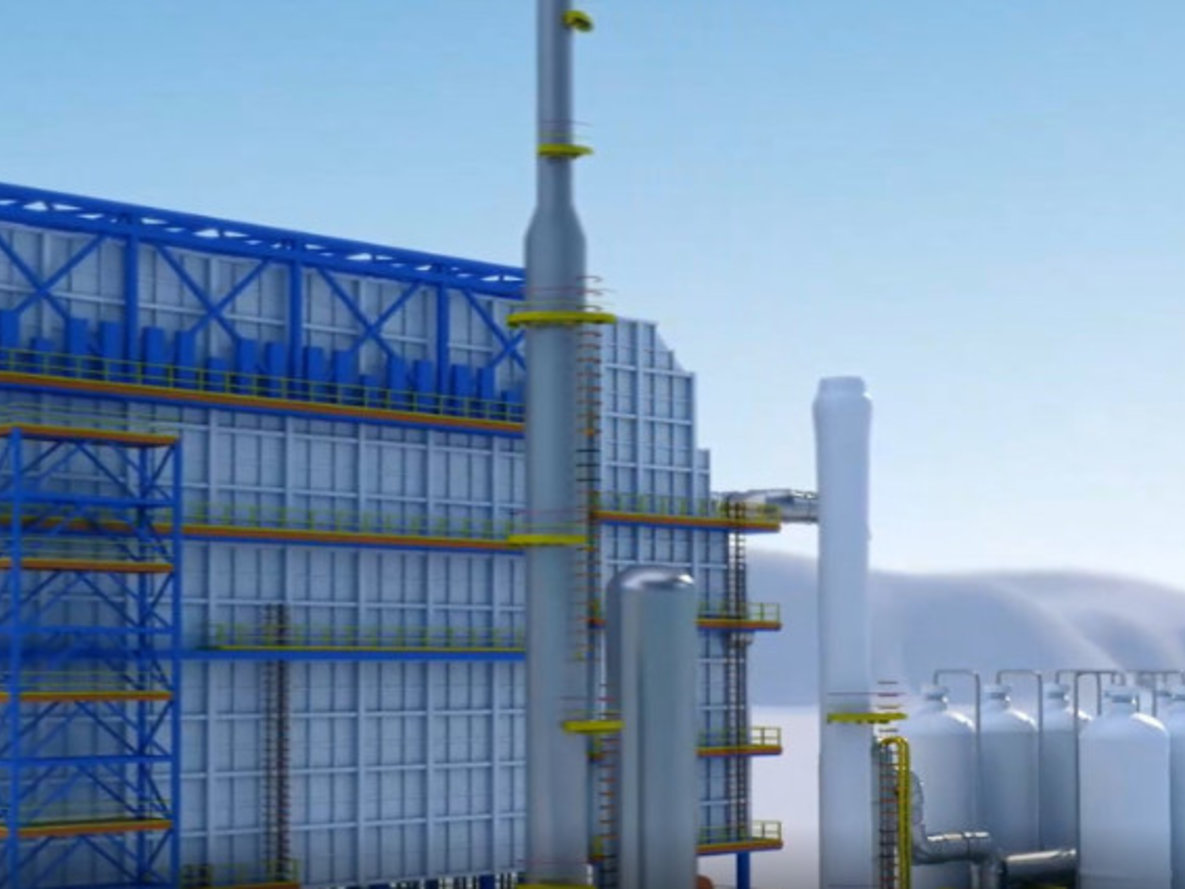

Air Liquide Engineering & Construction offers a portfolio of technologies for low-carbon hydrogen production, purification and recovery. The innovative technology solutions address a diverse range of needs and individual requirements of customers.

Autothermal Reforming

Autothermal Reforming (ATR) is a process for producing syngas, composed of hydrogen, carbon monoxide and carbon dioxide. The ATR process, when combined with CO-Shift and carbon capture technology, is one of the most cost effective solutions to produce low-carbon hydrogen at scale.

Air Liquide is the only company that has all the proprietary technologies and capabilities needed to combine ATR with carbon capture technology into a seamless integrated technology chain. For this, we provide a range of carbon capture technologies suitable for ATR.

We have a proven track record, successfully designing, integrating and operating ATR plants, including 12 large ATR plants with a single-train ATR capacity of up to 450,000 Nm³/h syngas.

Steam Methane Reforming

Steam Methane Reforming (SMR) is a long proven, highly cost-effective and energy efficient way of producing hydrogen. Today, we provide SMR technology for hydrogen production on both a small and large scale with carbon capture and storage.

Our technology allows for flexible utilization of feedstocks, and designs may be optimized for lowest operating expenditure, highest efficiency or lowest total lifecycle cost. Different degrees of modularization and standardization can be applied to meet project requirements. For all plant designs, excellence in availability and reliability remains a prime focus. In this area, our customers benefit from Air Liquide’s vast experience in operation with our own large portfolio of steam reforming plants.

Gas Partial Oxidation

Gas Partial Oxidation (GasPOX) is a technology used as a method for producing syngas or pure hydrogen, without the use of a catalyst.

GasPOX is a proven process, well-referenced and with lower capital costs than other methods of syngas production. These features have resulted in growing market interest in this technology in recent years. The POX technology is of particular interest for clients who want to turn crude syngas from a biomass gasification into renewable syngas and hydrogen.

Pressure Swing Adsorption

One of our technologies, known as Pressure Swing Adsorption (PSA), can recover and purify hydrogen from a wide range of hydrogen-rich streams.

PSA is an effective method of producing very pure hydrogen ‒ reaching purity levels of more than 99%. The units that carry out this process are compact and skid-mounted and designed for unmanned, automatic use.

Hydrogen Membranes

Air Liquide has developed unique expertise for high-performance hydrogen membranes. Membranes can be used on a stand alone basis for recovery of hydrogen from a process stream (such as ammonia purge gases), or integrated in a Cryocap™ H2 to debottleneck hydrogen production from an existing Steam Methane Reformer while capturing CO2 from process gas.

CO₂ Capture and Liquefaction

A distinctive aspect of our CO₂ management is our range of technologies which allows us to serve many customers and industries to decarbonize their processing facilities.

One of our key capabilities is our market-leading development and application of cryogenic processes, which involves the use of extremely low temperatures to separate gases. One of our principal range of products developed in this area is known as Cryocap™.

With our proprietary technologies for CO2 capture (Cryocap™, Recticap™ and for integrated impurity removal, Rectisol™), and our referenced experience in the application of amine washes, coupled with our extensive operational experience, we have a range of highly competitive and tried-and-tested solutions for CO2 capture.

Ammonia as a Hydrogen Carrier

Ammonia, with its potential for decomposition into nitrogen and hydrogen, can play an important enabling role in establishing hydrogen as an integral part of a low-carbon future.

Air Liquide offers customers access to low-carbon ammonia production concepts. With our expertise for large scale hydrogen production, nitrogen production and carbon capture technologies, we offer solutions beyond the conventional ammonia production routes.

With our support, customers can benefit from seamless integrated low-carbon ammonia production concepts at scale. With the addition of the necessary infrastructure for transport and storage, customer needs can be complemented to make ammonia a valuable low carbon energy carrier.

Once transported, ammonia can be readily re-converted to create a valuable hydrogen supply.

-

Hydrogen production

Download the document PDF (3.03 MB)