Air Gases

A wide range of standard and customized air separation units and cryogenic liquefaction technologies

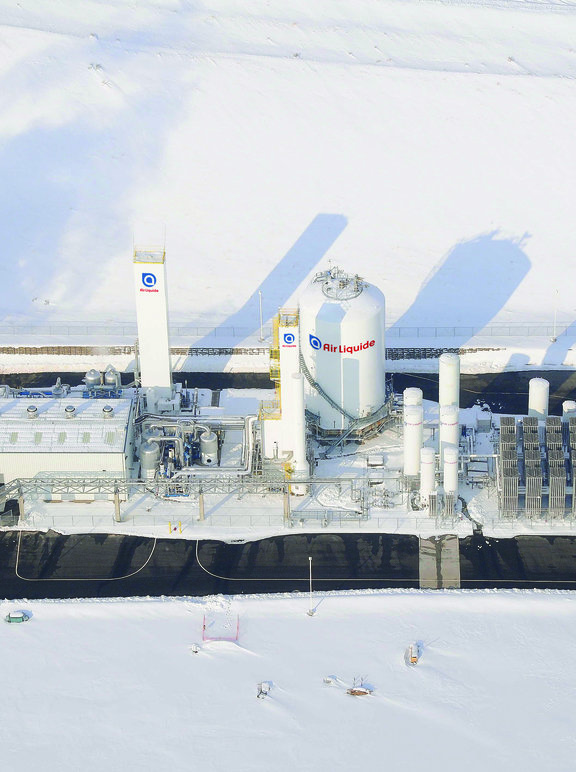

The air we breathe contains gases like oxygen and nitrogen that are essential to our customers. Air Liquide Engineering & Construction’s world-leading expertise and experience means the operation of our air separation facilities is not only adaptable to the different needs of those customers, but is safe, energy-efficient and making a meaningful contribution to cutting carbon emissions.

We have the experience, flexibility and capacity to provide a wide range of air separation units through standard plants, customized offerings and other cryogenic liquefaction technologies. Our strength lies in our ability to adapt our plants performances, safety and construction design philosophy to each project and customer’s specifications.

Air Separation Units

Air separation to deliver the industrial gases that our customers need is at the heart of our business and is a fundamental part of our history. Building on our many years of oxygen production, we offer a range of air separation units for customers, delivering the gases that they need for their industrial processes, at varying levels of purity/pressure – whether that be oxygen, nitrogen, liquid oxygen, liquid nitrogen, liquid argon, or others.

We have extensive experience in the design and construction of Air Separation Units (ASUs) that meet specific requirements and also have the capacity to offer modular approaches. ASUs can be configured to optimize capital or operational expenditure, as required.

Our ASUs serve well-established markets in sectors including metals production, chemicals, glass, pulp and paper to name just a few. We are also supporting the energy transition by developing ASUs which enable energy storage, helping to manage the grid intermittency that results from increased renewable power generation.

In addition, as part of our own efforts to minimize greenhouse gas emissions, we continuously strive to improve the energy efficiency of our ASU portfolio. In line with Air Liquide’s sustainability objectives, which include reaching carbon neutrality by 2050, our recent investment in an ASU in the state of Uttar Pradesh in India has been designed to operate fully on renewable energy by 2030. By doing so, it will make a positive contribution to the energy transition in India.

Nitrogen generation systems

Nitrogen generation systems are safe, reliable, and easy to both operate and maintain. While these are typically provided through standard plants – highly packaged, modular units which can be easily and quickly integrated into industrial complexes – several options are available, depending on customer needs.

Air Liquide Engineering & Construction’s nitrogen generation systems can be configured to optimize both capital expenditure (CAPEX) and operational expenditure (OPEX), depending on customer requirements. Production capacity can range from 500 to more than 60,000 Nm3/hour.

Nitrogen generation systems are typically installed in chemical complexes and serve the electronics market. For the electronics industry, which uses large quantities of ultra-pure nitrogen in the manufacture of chips for computers and mobile phones, we have developed an ultra-pure nitrogen generator which reduces energy consumption by about 30%.

Rare gases

We are a world leader in the delivery of rare gases for our customers – such as helium, neon, krypton and xenon. While these often have highly specialized applications, such as in aeronautical, lighting, and electronics sectors, we have the capacity to produce and deliver them on an industrial scale.

We use leading-edge, energy efficient technologies and advanced analytical equipment to produce these gases through units that are integrated with existing air separation units or as a standalone facility. They are delivered as assembled packages or on skid units to ease their installation. The gases can be supplied to varying levels of purity, depending on customer needs, including ultra-high purity.