Renewable Hydrogen

Hydrogen produced from renewable sources has the potential to be a critical enabler of the global transition to sustainable energy and net zero emission economies.

Air Liquide Engineering & Construction is supporting the energy transition by providing technologies and commercial ventures that will drive the development and application of renewable hydrogen.

Electrolyzers

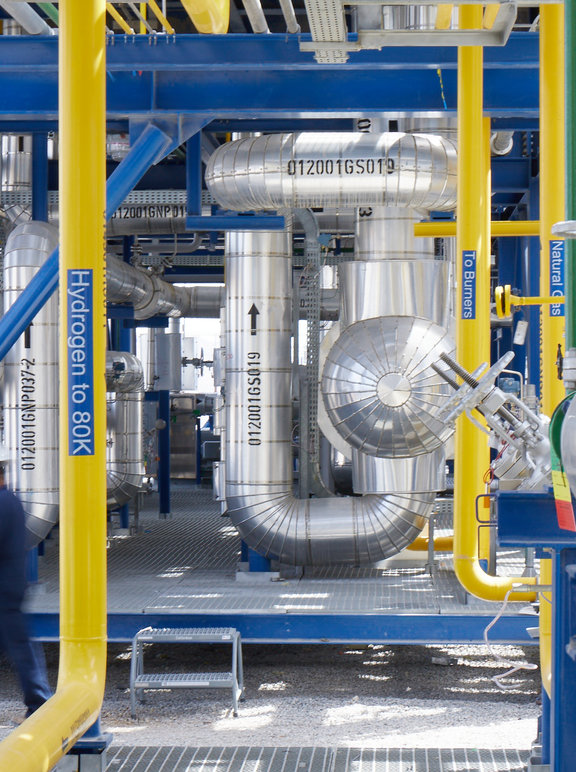

A core technology in carbon-free hydrogen production is electrolysis ‒ the process of splitting water into hydrogen and oxygen by applying an electrical current.

We have proven experience of electrolysis on an industrial scale and have made some of the largest industrial investments ever seen in this technology.

Our offer to customers includes either proton exchange membrane (PEM) or alkaline (AEL) technologies.

We also have extensive project experience across the spectrum of electrolysis technologies, with world-leading downstream technologies and experience, in liquefaction and compression.

In partnership with Siemens Energy

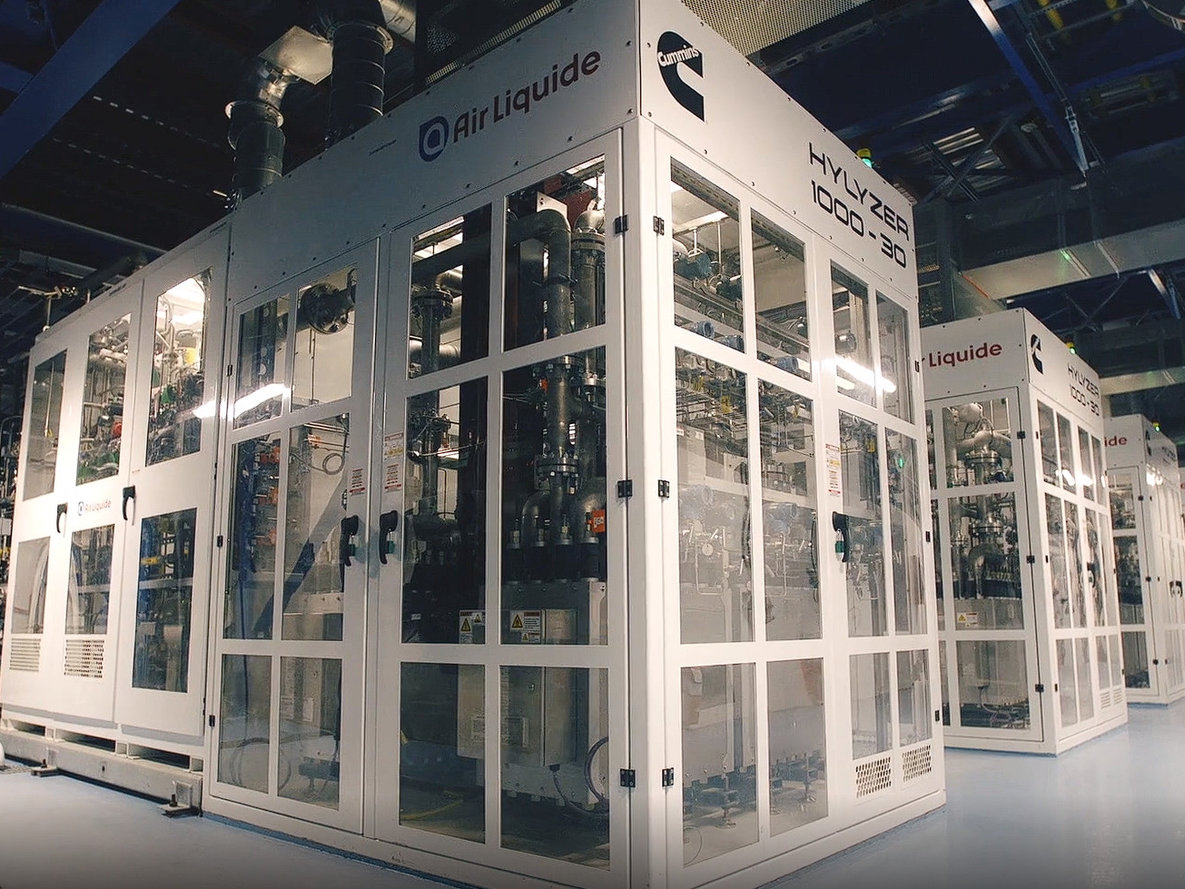

Our capability has been reinforced by our joint venture with Siemens Energy, producing industrial scale renewable hydrogen electrolyzers for customers worldwide. The partnership is strongly supporting the emergence of a sustainable hydrogen economy in Europe and is helping to foster the European ecosystem for electrolysis and hydrogen technology needed to forge the energy transition.

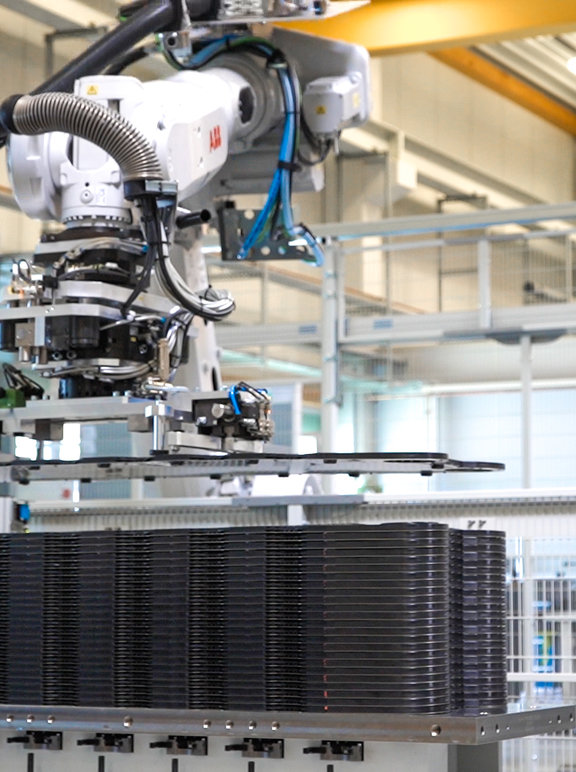

The joint venture has inaugurated a gigawatt electrolyzer factory in Berlin which will enable the manufacture of low-carbon hydrogen at industrial scale. The 2,000 square meter state-of-the-art facility uses automation and robotics for the production of Proton Exchange Membrane (PEM) electrolyzer modules. The modules feature a high degree of efficiency and are ideally suited to harvest volatile renewable energy. Annual production capacity at the factory will ramp up to three gigawatts by 2025.

This strategic partnership benefits from a portfolio of hydrogen projects, combining both Air Liquide and Siemens Energy’s pipelines, targeting large industrial-scale projects worldwide in collaboration with customers. In Europe, a number of low-carbon and renewable hydrogen projects are already under development which draw on the expertise of both groups:

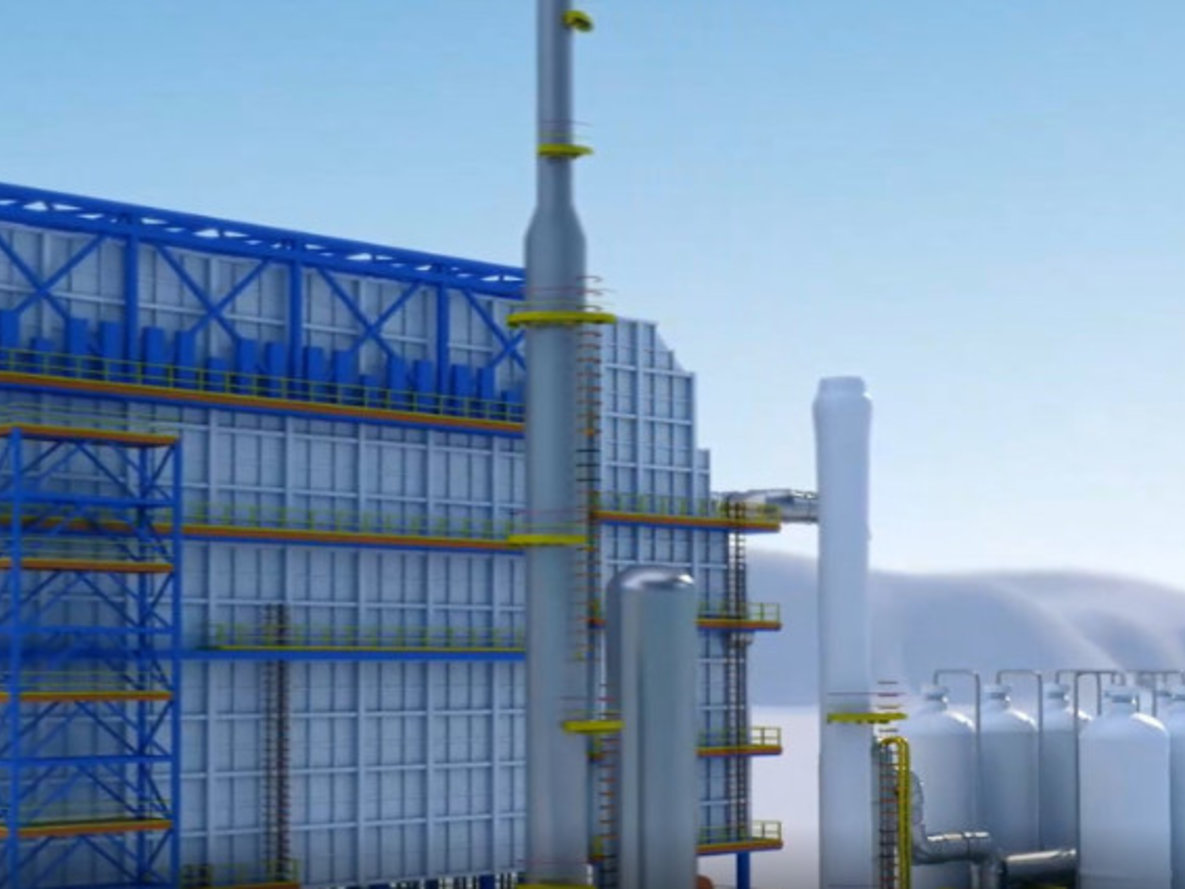

Integrated Power-to-X plants (PtX)

The conversion of electricity into chemical energy is called PtX where the ‘X’ may represent liquid hydrogen, methanol, ammonia or other energy carriers.

For these three options, Air Liquide Engineering & Construction is able to deliver integrated production plants, optimized for a direct coupling with fluctuating renewable energy sources. For example, a CO2-to-methanol plant consists of an electrolyser, a carbon capture unit and a methanol production plant. As we possess all three of these technology elements, we are in a unique position to deliver superior integration concepts by also leveraging our experience in hydrogen storage and adding flexibility to the downstream process. The same capability applies to integrated liquid hydrogen plants and we are also able to integrate ammonia synthesis to produce Green Ammonia.

-

Hydrogen production

Download the document PDF (3.03 MB)